What types of materials are banners made of?

This is a good question and is quite simple on the surface, although there are many variations within each category.

The two main categories of banner materials: vinyl (PVC) and fabric or cloth banners. That's the easy answer.

However, it is helpful to know the variations within each category, so I'll start with the vinyl banner category first, as it's simpler, I think.

First off, PVC or vinyl banners come to us as roll stock, and we either screen print (becoming less common), or digitally print these banners on a wide format digital printer.

There are several weights available, the most common being (at least in our shop) 10 oz., 13 oz., 15 oz., and 18 oz. The ounces refers to the weight of the banner per square yard of material. The heavier the weight, the more durable, although installation methods are often of utmost importance in the life of any outdoor vinyl banner.

With these materials, most are also available with a block-out layer between the sides that allows us to print both sides of the material without having a shadow show through the back side.

Another type of vinyl banners is the mesh vinyl banner, which is a perforated material that is printed with a backing sheet on it to prevent ink from spraying all over the printing platen on the digital printer. This material allows a certain amount of wind to pass through it, thus reducing the wind load from 10 to 20% on average.

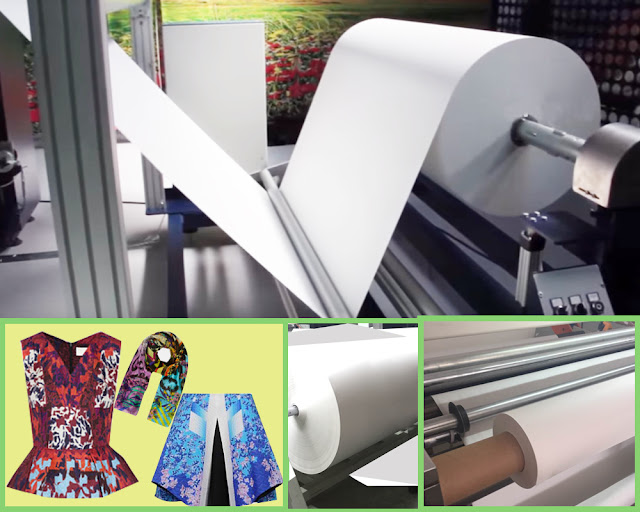

The second main category is fabric banners, which are most frequently made using polyester, nylon, or other synthetic fabrics. Most of these banners are currently printed using a printing method called dye sublimation printing.

Some street banners and cloth banners are also screen printed if the volume of printing justifies setting up the screens to do so, or the print shop specialized in street banners created by screen printing.

Dye sublimation digital printing of banners is one of my personal favorite advertising graphics to sell. It is very classy compared to vinyl banners, so much so that they have taken over the high end trade shows as the banner of choice, at least for companies that don't want to appear cheap.

The dye sub print process uses heat and pressure to transfer the CMYO print from the transfer paper to the synthetic fabric itself. Over the past few years, digital direct to substrate dye sublimated printing has started to take over the fabric banner industry because it has less steps involved in printing a banner using dye sublimation that the heat and pressure method. I.e., it's faster and cheaper to produce, so many printers are switching to this type of printer for those reasons.

Within the fabric category, the main differences you'll find is in the materials. There are dye sublimate printed satin fabric banners, stretchy fabric banners (polyester with Lycra or the like), outdoor polyester banners, acrylic banners, and nylon banners. There are polyester fabrics that are sheer, look like cotton, or any number of variations.

So, as you can see, there are many options for printed fabric banners available, whether they use the traditional dye-sublimation printing method or the DTS (direct to substrate) printing method. Or screen printing. Lots of ways to produce a fabric banner, and for interior use, I personally would almost always recommend dye sub printed cloth banners.

Follow Us: