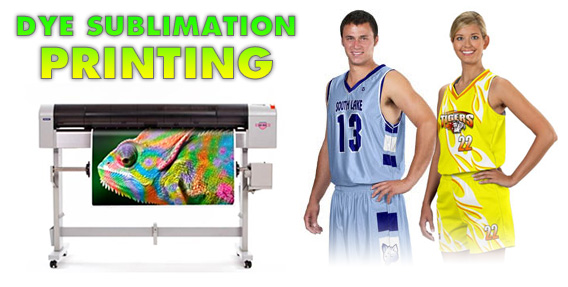

How Does It Work?

Digital textile printing is ink-jet technology that can print designs directly onto a garment, a t-shirt or dress for example, or can be used to produce larger quantities of fabric. It’s similar to an ink-jet paper printer, really!

In the past, rotary screen printing was used to produce large quantities of printed fabric. In rotary screen printing, each run usually produces several thousand yards of printed fabric. One of the advantages of digital textile printing is the ability to make smaller runs.

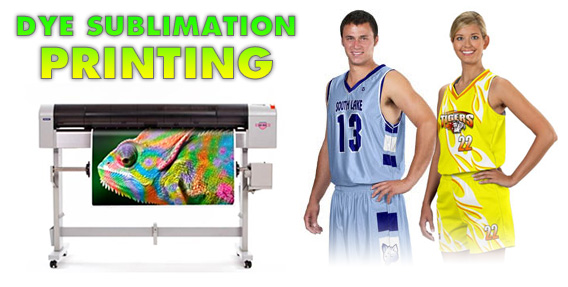

Different Sublimation Dye Inks are used depending on the type of fabric (polyester, lycra, spandex, etc). During the printing process, fabric is run through rollers, while ink is applied to the surface. After this, heat and/or steam is used to cure the ink, and “set” it into the fabric.

Designs can be created digitally, using any graphic design software, like Photoshop. Existing images can also be used, whether scanned or found online.

What Are The Benefits?

There are several benefits to digital textile printing, including:

- Virtually endless creative freedom:

- Small batches:

- It’s fast:

- It’s environmentally friendly:

If you can create it digitally, you can print it! Digital textile printing means a world of creative possibility.

You can make runs as small as one yard, versus the several thousand usually produced in traditional textile printing. This is helpful if you just want to create a few garments, or if you want to customize each run.

You can have your finished prints within days or weeks, depending whether you have a printer onsite.

Digital textile printing uses precise measurements of inks and dyes when printing, resulting in little to no waste. Everything is printed “on-demand.”

No comments:

Post a Comment